I. Project summary

After on-site investigation and analysis of the leakage parts of the apartment building bathroom, after the bathroom decoration is used, the water penetrates from the brick joint and accumulates in the filling structure between the waterproof layer and the brick. If the waterproof layer is a material that is not resistant to water for a long time, a certain time The weak part of the waterproof layer is infiltrated by water, and the water-resistant structural defect cracks leak to the back and downstairs, and the leaking stain spreads around the crack, and the structure is wet for a long time, destroying the decorative effect. Because the bathroom door can't stop the water, the saturated water under the brick diffuses through the door and diffuses into the floor of other unwaterproof rooms, leaking from the structural defects to the lower floor of the floor, and damages the decoration of the downstairs. If the effective water and impermeability treatment is not carried out in time, the structural steel will be rusted and peeled off, resulting in more serious safety hazards.

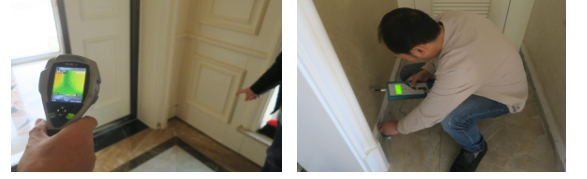

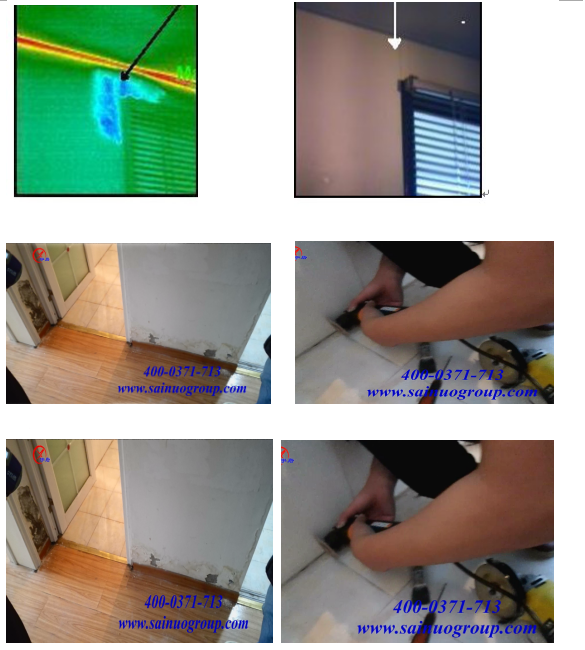

The picture of the leaking part is as follows:

Second, the analysis of the cause of water seepage

In view of the actual situation of water seepage on the back of the lower floor and the back wall of the floor, the application of professional scientific leak detection technology, combined with the results of on-site leak detection, and the structure of the project, the original waterproof treatment, etc., comprehensive analysis to find out the leakage main reason:

1. Reasons for waterproofing: The original structural waterproof layer is ineffective, and the water leaks into the downstairs.

2, structural reasons: the cracks, looseness, voids and other defects of the floor structure construction, and the waterproofing of the boarding pipe is not dense, resulting in the floor board losing its self-waterproof function.

3, water supply and drainage system: detection and inspection of concealed water supply and drainage pipes, blocking the source of water leakage, fundamentally and thoroughly.

The main cause of the above leakage is that the original water surface waterproof layer is damaged and the drainage is not smooth, the floor water is accumulated, the structural defects are not dense, and the loss and the self-waterproof function cause leakage.

Third, comprehensive management solutions

1. Leakage instrument detection, accurate analysis and positioning, find the source of leakage water, block the source of water leakage, strengthen waterproof, and fundamentally thoroughly control.

2. Replacement maintenance of water supply and drainage system, water supply and drainage pipe fittings, valves, etc.

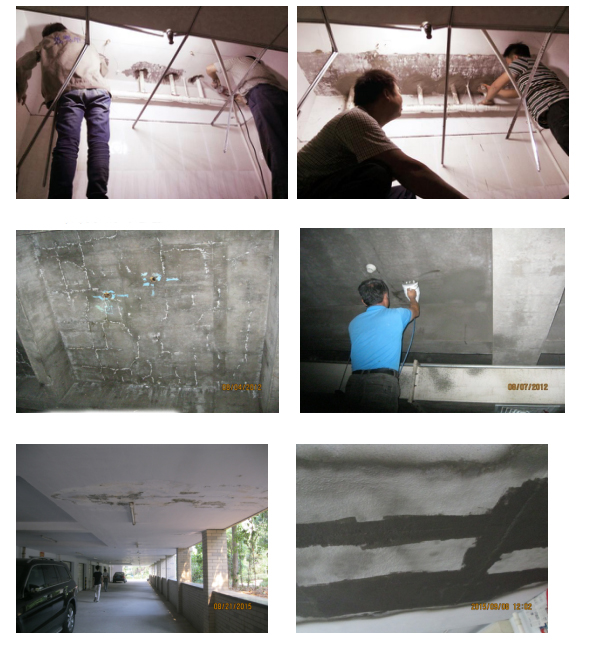

3. The backwater surface adopts structural defect reinforcement, impermeability and plugging measures:

a. Remove the coating of the coating mortar from the leaking part, crack the groove and the circumference of the pipe, and clean the base surface with high pressure water spray;

b. Crack infusion YY-17 Lycra resin repair, brushing RD-FLEX back pressure a coating, tube circumference and loopholes, etc., using YY16 flashing plugging slurry to seal the water;

c. The leakage surface is entirely coated with a special slurry for RD-N redundant top plate.

4, the water surface is not damaged by the floor tiles, does not affect the appearance of waterproof plugging materials, technical construction:

a. The concrete structure of the original floor is connected to the original floor to make a water blocking measure 10mm higher than the existing floor surface;

b. Electric cutting open the original brick seam, clean, high pressure spray YY-1 slurry, the blade is filled and compacted, after 12 hours, repair the caulking, remove the residual residue of surface bonding, clean the seam Repeatedly brushing YY-1 liquid material, after 12 hours, it can be closed water test, and no leakage after 24 hours can be accepted for acceptance.

Fourth, the use of technology, materials

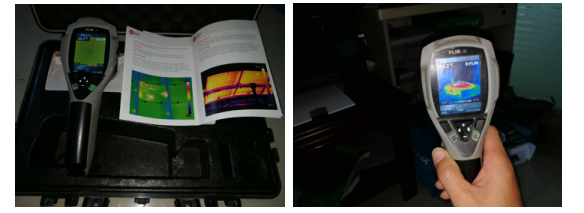

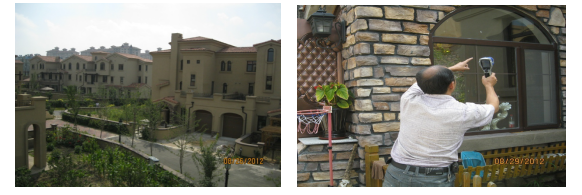

On-site excavation verification based on the thermal image diagram formed by the infrared thermal imager and the microwave humidity test system to detect the temperature of the surface of the leaking toilet component and the moisture and leakage determined by the microwave moisture distribution map drawn by the relative moisture content Analysis, using symptomatic materials, design and improve the feasibility of the construction program.

Design the overall structure reinforcement, anti-seepage and plugging treatment scheme, without destructive excavation, the backwater surface adopts YYA special waterproof impermeability, YY16 flash coagulation plugging enhancement, YY-17 special Leica resin, RD-FLEX back pressure coating Ling, RD-N redundant roof special slurry construction, YY-1 leakage and sweeping brick joints on the water-facing surface to construct a high-strength two-way multi-waterproof impervious system to completely solve the problem of kitchen leakage.

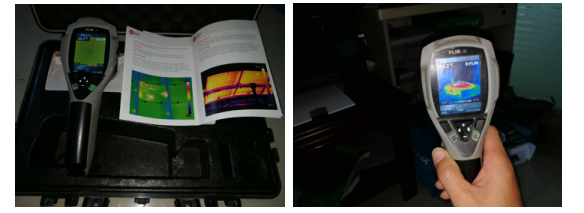

a), testing equipment:

In the actual project, the infrared thermal imager and the microwave humidity test system are combined, and the thermal image formed by the temperature of the surface of the component and the microwave moisture distribution map drawn by the relative water content are used to effectively determine the defects such as moisture and leakage. range.

Thermal imaging camera:

Infrared thermography is a non-contact non-destructive testing method that uses an infrared thermal imaging device to capture the temperature distribution of an object surface into a visible image for analysis.

Infrared thermal imager is an infrared imaging system that can generate thermal images based on the principle of surface radiation temperature. It consists of thermal imaging detection device, thermal imaging control device and peripheral equipment such as image processing, analysis storage and output.

Firstly, the infrared radiation image is used to detect the radiation temperature of the object on the surface of the quality defect of the construction project and form a thermal image map. The suspicious area is determined, and then the relevant area is detailed, and the type and degree of the defect are analyzed in combination with relevant engineering drawings.

Microwave humidity test system:

Microwave humidity test system is an emerging building leakage detection technology, which is non-destructive, fast and efficient. The microwave humidity test system uses the specific frequency of 2.45GHz in the wide microwave spectrum for building leakage detection.

Since there is a large difference between the dielectric values of the water molecules and the component materials, even a small amount of water molecules can be detected in the component materials. Rapid microwave detection is performed at different positions and depths on the components, and the data is combined into a planar or three-dimensional microwave humidity distribution map by a computer, thereby effectively determining the internal humidity and leakage parts and ranges of the components.

b), main material properties:

1, YYA special waterproof impermeability slurry

YYA special waterproof and anti-seepage slurry is developed by Zhengzhou Sainuo Building Material Co., Ltd. It is a special-purpose rigid internal waterproof material for treating concrete and masonry structure leakage in the back water surface. It is a new special effect waterproof and impervious material, non-toxic and tasteless. , flame retardant, environmentally friendly, can be used in food and drinking water projects. It is a gray powder composed of dozens of pure inorganic components. It has a single component and various components react with water to have multiple waterproof and impermeability functions, and has high strength (7 days C30 or more) and high and low temperature resistance (- 40-200 ° C), strong bonding force (2.0 MPA), impermeability pressure up to 1.8 MPA, can withstand the pressure of 180 m water column, no layer, no cracking, UV resistance, aging resistance, antifreeze, not easy to be destroyed, No lap joint construction, high reliability, can quickly solve the problem of water seepage in the basement, water seepage in the underground garage, water leakage in the basement, water leakage in the underground garage, water leakage in the pool, water seepage in the tunnel, water leakage in the cable trench, and other large-area seepage and brick-concrete structures. The effect is durable. It has been tested by the National Building Materials Testing Center and is listed as a key application and application product in China's engineering construction. It is the best choice for durability and waterproof engineering. This material is sprayed, even if high pressure grouting or other materials are not effective, the use of this material can still achieve the desired results.

YYA special waterproof and impervious slurry is the main material for internal waterproof construction and has the following advantages:

1) Excellent water and impermeability, it is a true multi-dynamic waterproof material;

2), with concrete, masonry structure has a strong bonding ability, can carry a large area of water on the back surface. Even in the case of leaking water that uses grouting or other materials that are not performing well, the material can also achieve the desired results;

3), using spray method construction, the thickness of the waterproof layer is uniform, no seams, and the thickness of the material can be adjusted according to the construction requirements, which is suitable for local repair treatment or large-area construction.

4) It integrates waterproof, impermeability, repair, reinforcement and protection. It does not need another protective layer. It has high compressive strength and flexural strength, can withstand high water leakage pressure, and effectively increase the strength of buildings.

5), composed of pure inorganic materials, with the same life of concrete structure, high temperature resistance, UV resistance, antifreeze, anti-aging.

6) Non-toxic and tasteless, true green products can be applied to food engineering and drinking water projects.

The material is used in a wide range of applications: basement, underground garage, civil air defense, tunnel, subway, cable trench, elevator shaft, cable well, valve well and other underground engineering leakage water, as well as various concrete such as pool, dam, hydraulic engineering, etc. Water leakage from the masonry construction work.

This material is often used for the treatment of large-area concrete seepage or large-area brick-concrete structure seepage water base.

2. YY-16 flashing paste:

Developed by Zhengzhou Sainuo Building Materials Co., Ltd., it is an inorganic high-strength impervious material, which is used for the leakage of concrete or the leakage of brick-concrete structure.

It can be combined with the concrete base layer and combined with YYA special waterproof and impermeability slurry.

3.YY-1 tile leaks a spray:

Developed for Zhengzhou Sainuo Building Materials Co., Ltd., the materials are classified according to the construction steps, and are composed of YY-1 powder and YY-1 liquid material. When used, the powder is firstly added with water to adjust to a putty-like embedded compaction, and after the consolidation, the coating liquid is infiltrated. It is applied to the maintenance and treatment of leaking water in various buildings such as kitchens, bathrooms, swimming pools, landscape pools, etc.

YY-1 powder is a one-component, gray powder, good waterproof and impermeability after consolidation, small shrinkage, no delamination, no cracking, water pressure resistance, high and low temperature resistance, UV resistance, dry and wet resistance, durability excellent.

YY-1 liquid material is a one-component, pure inorganic liquid, UV-resistant, colorless, odorless and non-toxic. The construction penetrates into the concrete base surface to react, quickly close the loose pores of the concrete base layer, prevent the infiltration of water molecules, and withstand certain water. Pressure, effectively improve waterproof reliability. It is used for the maintenance and treatment of leaking water after paving tiles in kitchens, bathroom swimming pools, landscape pools, etc.

4, RD-N redundant backplane special waterproof paste

Developed by Zhengzhou Sainuo Building Materials Co., Ltd., RD-N redundant base plate special waterproof paste, combining the advantages of rigid materials and flexible materials, adding a variety of unique material components and active factors, excellent waterproof and impermeability, Long-term water-resistant immersion, with double waterproof effect, not easy to be damaged during construction, the waterproof layer is damaged and not easy to leak, which can greatly improve the reliability of building waterproofing.

Specially used for underground engineering (including hollow box structure) waterproof material in a large area, rigid and soft, strong adhesion on the back water surface, excellent waterproof and impermeability, long-term immersion resistance to water, can withstand a certain water pressure on the back surface, prevent moisture Infiltration. The product is suitable for the base layer: concrete, brick wall, mortar layer, marble or ceramic tile, etc. The base layer can be applied both wet and dry.

Scope of use: Wide-area waterproofing of various underground projects such as various basements, underground garages, cable trenches, and urban pipe corridors.

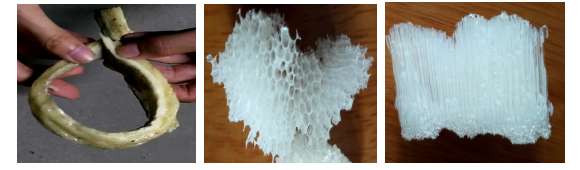

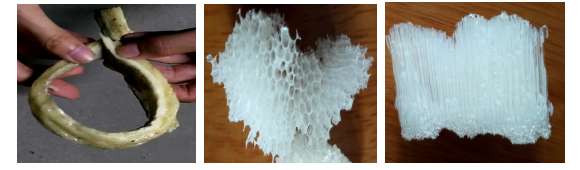

5, YY-17 Lycra resin (active crack leakage a note)

YY-17 special Lycra resin is developed by Zhengzhou Sainuo Building Materials Co., Ltd., which is a new type of grouting material with higher reliability than ordinary foamed polyurethane. Two-component, no solvent dilution, low viscosity, high elasticity and strong adhesion. The characteristic is: strong bonding force, no matter whether the base layer is wet or dry, it can be tightly bonded with the concrete, and the crack continues to deform and is not easy to fall off; the viscosity is low, and it can effectively penetrate into the concrete capillary hole of the concrete; has good elasticity It can quickly fill cells or gaps that appear due to defects in the base layer or continue to deform.

Comparison of ordinary foamed polyurethane RD-17 special Lycra resin

Watery environment, water swelling, water swelling

Anhydrous environment will not swell, keep the original shape, form a special rubber, seal moisture penetration

Medium viscosity, low fluidity and permeability, good fluidity and permeability

Very good elasticity

Toughness is generally good

Poor adhesion, good

Forming an elastomer shape Unclosed coarse foam elastomer, easy to leak Water Closed fine honeycomb elastomer, not easy to leak

Is it resistant to water for long-term soaking?

Suitable for PH environment below 9, above 9 is easy to separate from the concrete base layer 12 or more, not easy to

Concrete base detachment

Static crack leakage suitable for

Active crack leakage, not suitable

Grouting pressure High pressure, easy to damage

Concrete structure, low pressure, not easy to damage

Concrete structure

Poor durability, good

The ordinary polyurethane grouting material has high viscosity, easy shrinkage, and no adhesion to alkaline moist concrete, and the hysteresis rate is high, and the effect is not durable.

6, RD-FLEX crack leakage a coating

RD-FLEX crack leakage is a coating, two-component, strong adhesion, good waterproof and impermeability, and can treat the leakage of building cracks in the backwater surface. The material is used for internal waterproofing of construction projects, as well as for preventing leakage caused by secondary cracking of cracks, and can withstand a certain water pressure. The material is simple in construction, fast in speed, good in durability and high in reliability.

It is often used for the treatment of crack leakage water with no clear water.

The characteristics of crack leakage and coating:

1), waterproof and impermeability, water-resistant long-term immersion.

2), has good adhesion and folding resistance

3) Semi-rigid and semi-flexible, it can withstand a certain water pressure, and can also prevent water leakage caused by crack changes.

4) Good durability and high reliability. The construction is simple and convenient, and the speed is fast.

V. Leakage comprehensive treatment construction plan

After understanding the causes of leakage, according to GB50108-2001 "Technical Specifications for Underground Engineering Waterproofing", follow the principle of "combination of prevention, drainage, interception and blocking, rigid and flexible, local conditions, comprehensive management", according to the site leakage Different parts of the water are treated in different ways using different materials and construction techniques. Application of professional leak detection instruments and special materials, using comprehensive treatment technology to better solve the leakage problem.

The addition and reconstruction of the drainage pipeline shall be completed by professional hydropower technicians after the completion of the inspection by the professional leak detector or before the waterproof plugging construction.

Construction preparation measures: During the construction, take protective and isolation measures for the construction area, disassemble, install or remove the facilities and equipment that affect the construction in advance, protect the floor coverings, materials, machinery, safety, labor protection products, technical management, The construction personnel are ready to enter the site and comprehensively manage the construction technology. The completion of the construction process in the area shall be recorded and reported in time for inspection and acceptance. Construction materials archive backup.

Waterfront: waterproof and impervious construction scheme for bathroom floor

Construction essential steps:

1. The oil stain and dust of the floor tile surface, floor drain and caulking are completely removed and cleaned, the cleaning agent is cleaned, and dried for 24 hours to reach the construction conditions.

2. Hand-held cutting machine with thin cutting blade, carefully cut along the original brick wall and the ground, and remove the original joint filler. Do not exceed the thickness of the brick to prevent damage to the brick line. The drainage pipe fittings and the floor drain should be strengthened. The nozzle and the floor drain are sealed with rubber inflatable ball plugs to prevent the garbage from falling in. After the brick joint is cut, the dust in the joint is blown off with high-pressure air in time and cleaned.

3. If the floor of the bathroom door door can't keep the water, you can cut the water tank between the door frame and the concrete structure surface with a width of 50mm. The tank is filled with the mix of YY16 and YYA, which is higher than the original floor tile. Sticky and cut 50mm wide, long stone or floor tiles suitable for the width of the door, and double-sided arcs to form a water barrier.

4. The surrounding pipe fittings should be strengthened. After the construction is completed, it is protected. Tile caulking proportioned water preparation YY-1 tile leakage a spray spirit powder into a putty paste, high pressure sprinkler, blade filling compact, brick surface scrub clean, dry for 12-24 hours.

5. Sweep the YY-1 liquid material on the clean tile floor as a whole, and the caulking should be repeatedly applied again and again with a small brush in advance. Allow to dry for 12-24 hours, then test the water or open it.

6. The key points of the wall are treated in place, and the height of the wall is determined according to the height of the water. Generally, it is better than 300mm. Do not move the equipment parts as much as possible, and spray YYA dry powder or YY-16 dry powder to fill the caulking defects. After drying, spray the YY-1 liquid material as a whole.

Sixth, labor arrangement and project quality assurance

1. Do a good job in the construction of the construction personnel. According to the start date, construction section and labor demand plan, organize workers to enter the market in batches, live according to the arrangement, and conduct safety, fire prevention, civilized construction and law-abiding education.

2. All construction personnel who participate in the project must undergo technical training, understand the characteristics of the materials, master the construction process, carry out technical disclosure before construction, and strictly control the quality to ensure the successful construction.

3. Labor and Machinery Arrangement Schedule

Number of work grades

Field manager 1 person grout pump 1 set

Field engineer 1 person Distribution box, cable 2 sets

Technician and safety officer 2 people Safety work lighting 4 sets

Waterproof plugging technician 2 people Electric drill, cutting machine, mixer 3 sets

Excavator 2 people electric hammer 2 sets

Sprayer 2 people Air compressor, spray gun, air pipe matching 1 set

Dust mask 20

Other small tools, tools, buckets 1 batch

Brush, scraper, protective gear, rubber gloves 1 batch

Seven, to ensure safety measures

Safety management and measures:

After entering the construction site, the engineering department shall assume the responsibility for ensuring the safety of all personnel in the construction of the project until the completion of the project.

According to the relevant regulations of the government, in accordance with the actual situation on the site, formulate rules and regulations for site safety to ensure safe production.

(1) Safety technology disclosure system: According to the requirements of safety measures and the actual situation on the site, managers at all levels need to personally submit written reports. The safety technology must be signed and approved by the construction personnel.

(2) Pre-class inspection system: Professional foremen and regional construction workers must supervise and inspect the safety measures and safety protection items of the team.

(3) The acceptance system for the use of mechanical equipment: All those who do not experience it shall not be put into use. The equipment in use must be powered off after work and the special brake box is locked and protected.

(4) Safety activity system: The engineering department organizes relevant personnel to carry out safety education, summarizes the problems existing in safety, and makes necessary disclosures on safety priorities and precautions, so that the majority of workers can know what they are, and always tighten their safety from the consciousness. This string.

(5) Suspension system in critical situations: In the event of a crisis that threatens the life and safety of employees, it is necessary to stop work immediately, and immediately report the company and take timely measures to eliminate the danger.

(6) Construction system with certificate: It must hold the construction permit issued by the company.

(7) On-site personnel must ensure a good operating condition. Any hidden dangers that endanger safety can be used after passing the inspection. It is strictly forbidden to work with illness. New workers must be educated.

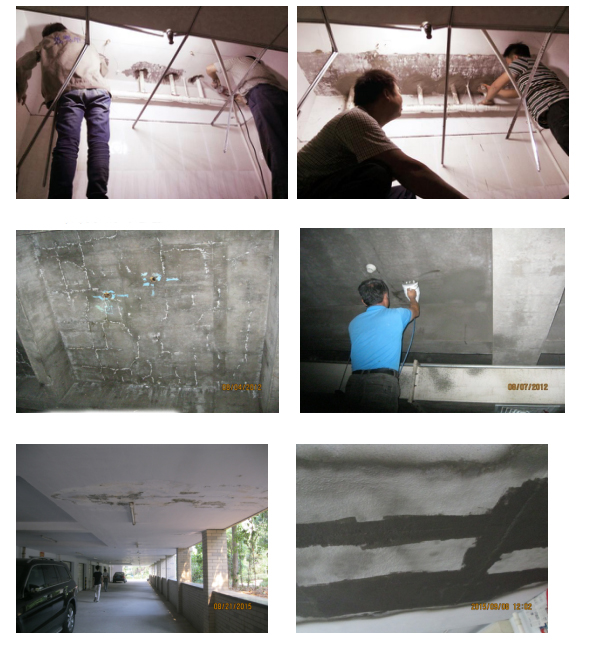

Eight, construction case

Nine, company profile:

Zhengzhou Sainuo Building Materials Co., Ltd. was founded in 2007 by a professional team with international multinational technical consulting background. It is a high-tech enterprise focusing on scientific research and development and technological innovation, mainly providing reliability sealing technology and concrete defects for construction projects. Repair protection technology.

Based on the international frontier, from the perspective of multi-disciplinary and comprehensive problem solving, the company puts forward the redundant sealing theory for the phenomenon of frequent leakage in China. It has developed redundant internal waterproof technology and redundant external waterproof technology (reliable reliability). 97%, and currently the leakage rate of building waterproofing reaches 80%), comprehensive waste utilization technology (sustainable development technology), to make up for the shortcomings of traditional technology, fill the gap in the market, and creatively solve the engineering field with high cost performance. A large number of construction problems have been highly recognized by customers.

The senior team members of Zhengzhou Sainuo Co., Ltd. have an international background, multi-professional integration, and have a strong competitive advantage in multi-dimensional innovation. The redundant sealing technology developed by the company has been published by many academic books and standard publishers.

Zhengzhou Sino

• The editorial unit of Engineering Redundant Sealing Technical Regulations

• “Construction unit for waterproofing engineering rules for exterior walls of concrete prefabricated components”

• The main editorial unit of the “National Building Waterproof Plugging Engineering Quota Manual”

• Deputy Chief Editor of the National Waterproof Plugging Technical Manual

Provide one-on-one expert technical consulting services, provide reliable durability solutions for difficult engineering problem systems, provide high-end technical products, and provide one-stop full-service services.

Free consultation phone: 400-0371-713 official website: http://sainuogroup.com/

X. Technical exchange and qualifications, certificates